How do operators innovative marketing from Internet

Recently, Dongguan’s first “factory” to start construction, the Pearl River Delta “machine substitution” strategy has begun to enter the implementation phase.

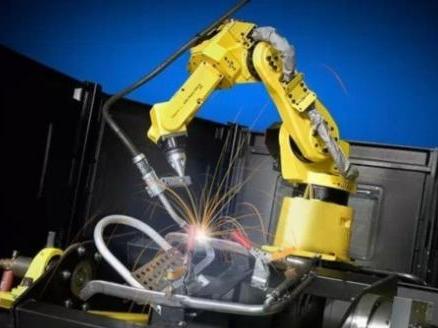

Factory called (all) automated factories, refers to all the production activities are controlled by the computer, and factory production line equipped with robots.

As a form of manufacturing plants in the future, the world’s earliest factory in 1984 Japan Tsukuba. The commissioning transcripts show that year:

Need hundreds of skilled workers in the past and the latest in computer controlled machinery, spent two weeks made out of small teeth turn, diesel engine, this factory only needed 4 workers spend a day can be produced.

As the demographic dividend of gradually falling as well as rising labor costs, already in the year 2013, China became the world’s largest industrial robot market. As of last September, about 420 domestic robots, and factory more than 30 provincial and municipal building robots.

Transformation and upgrading of the manufacturing industry in China, as well as “made in China” 2025 “the implementation of the strategy, to industrial robotics industry has brought great opportunities for development, this industry is expected to usher in the outbreak.

The building the unmanned factory in Dongguan, production and sale of mobile phone series connectors, shielding parts and ultra precision metal terminals and tooling. The factory first plans to invest 1000 unmanned robot, the 100 robots have been pioneered in the early “induction”. Project leader to the media, said:

Manual processing of NC machine tool before, often prone to security problems, the stability of product quality is relatively poor. Smart factory was built, through hardware robots to replace human, building a highly intelligent software control system, remote control, this will greatly improve the plant efficiency and product quality.

Data refers to, current employment gap has reached more than 100,000 people in Dongguan. Since the construction of the factory will relieve local many years of “labor shortage” problem. For those robots can “easily” the mechanical repetition of work done, this part of factory labor costs can also be reduced considerably. Although the acquisition of industrial robots a huge initial investment, but factories rising manpower costs and compared to the recruitment problem was “pale into insignificance”.

Looking at the long term, working with heavy machinery factory can make the vast majority of workers freed from the sea, and made products productivity 10 times or even 20 times more than doubled. This is trying to reverse a “sweatshop” image and promote industrial upgrading of China’s industries, is absolutely a major plus.

Robots than humans, have obvious advantages: 1. don’t know tired, can continue to operate its energy; 2. the lower the chance of error, most of the human history of factory accidents are caused by human error, robot is hard to go wrong in a set program unless the program itself is flawed. Humans tend to work with repeat, work longer becomes fatigued, and errors, the robot does not; 3. improved control precision, for some precision instrument operation, robot with a special arm, such as can be done without the slightest error, not many workers possess such qualities, 4. the most important point is that robot is cheaper in the long run input.

On “aggressively into the robot factory, migrant workers go from here?” Concern, I believe that labour shortage rather than a surplus of basic supply and demand is unlikely to change in the short term. Robot into the factory just to let some workers engaged in simple repetitive to seek more technical and intellectual content of new work. For a robot to do the most tired and dirty work, this is also manufacturing the “people-oriented” development trend. New era of intelligent workshop, blue-collar workers the same promising, such as those controlling the robot’s job.